In the first article posted to this website, I acknowledged the coffee percolator as the device that ignited my life long fascination with machines that have no moving parts. I remember being astonished that such a simple contraption should be able to perform the miracle of making 30 cups of coffee seemingly without effort.

Today, I want to spend a little time examining the coffee percolator to see how it works and maybe determine what it is that all machines with no moving parts have in common.

The Percolator: A Simple Brewing Machine

The coffee percolator, a stalwart of kitchens for decades, stands as a testament to the ingenuity of engineering. At its core, it is a machine that achieves its purpose without the need for any moving parts. Yet, it’s a marvel of fluid dynamics and heat transfer.

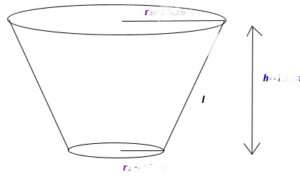

A percolator is essentially a vessel with a central tube that reaches nearly to the bottom. There is a basket containing coffee grounds at the top of the open tube. Water is heated at the base, and as it vaporizes, it forces its way up the tube, lifting the water column as it goes. At the top, the water runs out over the tube and percolates down through the coffee grounds in the basket. It drips back into the main chamber, where it is reheated, and the cycle repeats. The process continues until the desired coffee strength is achieved.

There are three distinct functions involved with the operation of a coffee percolator. None of these require moving parts to be realized.

-

Water lift:

To provide liquid to the basket, a bubble pump (sometimes called a pulsar pump) lifts a column of water through the central tube. -

Percolation:

The water then percolates down through the coffee grounds to extract flavors and color making coffee in the process. -

Filtration:

The coffee is filtered through a porous membrane, usually a disposable paper filter. This helps retain the grounds in the basket while allowing the coffee to slowly return to the reservoir.

The Working Principles

The key to the percolator’s operation lies in the interplay of heat, pressure, and gravity.

There are no mechanical pumps, gears, or motors involved; the process is driven solely by the physical properties of water and heat.

The heat source, typically an electric coil or gas flame, provides the energy to convert water into a gas, steam.

Lifting a fluid by gasses is not unique to coffee makers. Here are some other examples:

Geysers:

These natural phenomena occur when groundwater is heated by magma, creating steam that forces water to the surface.

Bubble columns:

These are industrial reactors where gas is bubbled through a liquid, promoting mass transfer and chemical reactions.

Thermosyphons:

A related device that rarely involves a lifting gas, thermosyphons use the natural circulation of a fluid due to density differences caused by temperature variations. They are often used in heating systems and solar water heaters.

While these examples might seem vastly different from a coffee percolator, they all share the underlying principle of fluid movement driven by pressure differentials.

Perks of Percolation

Percolation too is not unique to coffee makers. While the percolator is primarily known for its coffee-making abilities, the principle of percolation itself has far-reaching applications. In chemistry.

Filter washing:

Percolation is a technique used to separate components of a mixture. A solvent is passed through a filter containing the mixture, and different substances are extracted at varying rates. This process is essential in industries such as pharmaceuticals, food processing, and environmental science.

Water purification:

Water filtration systems often employ percolation through layers of sand, gravel, and charcoal to remove impurities. We recently posted an article on this very thing. This natural filtration process is a cornerstone of many municipal water treatment plants.

Cave creation:

Groundwater naturally percolates through rock and soil. This is important for clear, freshwater springs. Over millions of years and under certain conditions, this percolation can create limestone caves. As the water flows, it removes material by dissolving it away.

A Dawning Revelation

The percolator, with its simple yet effective design, showcases the power of fluid dynamics and heat transfer. It is a reminder that complex tasks can often be achieved through elegant and minimalistic means. By understanding the principles behind the percolator, we gain a deeper appreciation for the underlying physics at work in countless other systems, from coffee brewing to water purification and beyond.

Our detailed examination of the coffee percolator has exposed hints to answer our all consuming question:

“What do all machines with no moving parts have in common?”

And the answer is simple … Fluids.

A fluid is a substance that deforms continuously under the application of a shear stress, no matter how small the stress may be.

In simpler terms, a fluid is a substance that can flow and change its shape easily.

Key characteristics of fluids

- No definite shape; they take the shape of their container.

- Ability to flow under the influence of gravity or applied forces.

- Low resistance to shear stress.

In general, we can talk about two classes of fluids.

Physical fluids:

Fine particulate matter, liquids, gases, and plasmas.

Fluidic Energies:

Electrical currents, electromagnetic waves, sound, fields and thermal gradients.

Fluids are the unseen workhorses of many machines. All machines with no moving parts rely on fluids to do work and perform their function.

Often there are multiple fluids involved. The work is accomplished through changes in pressure, flow, volume, temperature, fields, frequency and other physical phenomena.

Moving forward, every time you encounter a new machine with no moving parts, I would urge you to analyze it to identify the fluid(s) it uses and the fluidic properties employed to make it function.